Excavator Pipe Handler

Excavator Pipe Handler

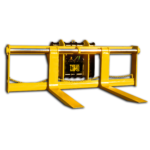

Bolted onto the inside of the grapple arms are UMHW wear pads specifically placed to minimize and prevent any wear that may occur while the operator is handling product. These handlers have the ability to handle pipe ranging anywhere from 6″ – 36″, 6″- 42″ or 12″- 64″ in diameter. Larger diameter pipe handlers are also available upon request and can be custom manufactured to customer specs. The large range of pipe diameters enables the pipe handler to far surpass the modern way of laying pipe with a sling and bucket.

Equipped with 2 Vis Eaton rotate motors for performance and handling, as well as heavy duty cylinders manufactured by Red Raven Hydraulics Inc. The excavator pipe handler is not only effective, it’s also heavy duty and durable.

Pipe Handler Features

- Optional handling capabilities ranging from 6″ – 64″ diameter pipe

- 2 -Vis Eaton rotate motors

- Hydraulic cylinders manufactured by Red Raven Hydraulics

- UMHW wear pads on grapple arms

- 360° rotate

- Heavy duty rotate bearing

- Left and right tilting

- Full range open and close to customer specs and pipe diameter preferences

- Custom built to customer specs

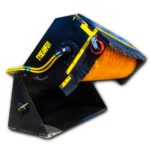

Our state of the art IFM German manufactured led touch screen is installed inside the cab of the machine for easy access. This enables the operator full control of changing pressures and speeds with ease when handling different materials, all without ever leaving the cab.